Top Suppliers Screen Separator Machine - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu

Top Suppliers Screen Separator Machine - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu Detail:

Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

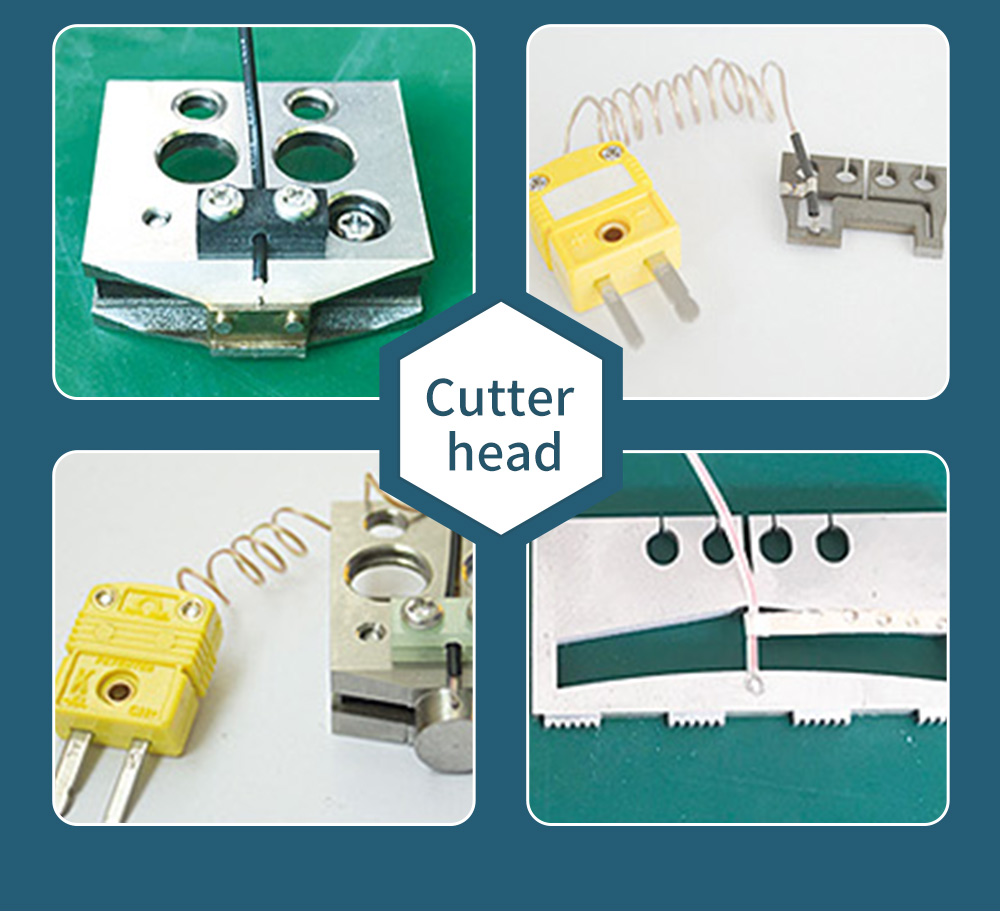

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Do digital technologies widen productivity gaps? Search The Brookings Institution The Brookings Institution Search Menu Twitter Twitter The Brookings Institution Facebook Twitter YouTube Podcast Browse Newsletters RSS The Brookings Institution Close Close | 2 In 1 Glass With Bezel Frame

Galaxy S10 Plus ceramic vs. glass: Which phone survived our drop test? | Assembly Machine

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Top Suppliers Screen Separator Machine - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu, The product will supply to all over the world, such as: Czech Republic , Frankfurt , New Orleans , we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.