Pulse Heat Press Machine For Projector Driver Film Bonding Jiutu

Pulse Heat Press Machine For Projector Driver Film Bonding Jiutu

Function :

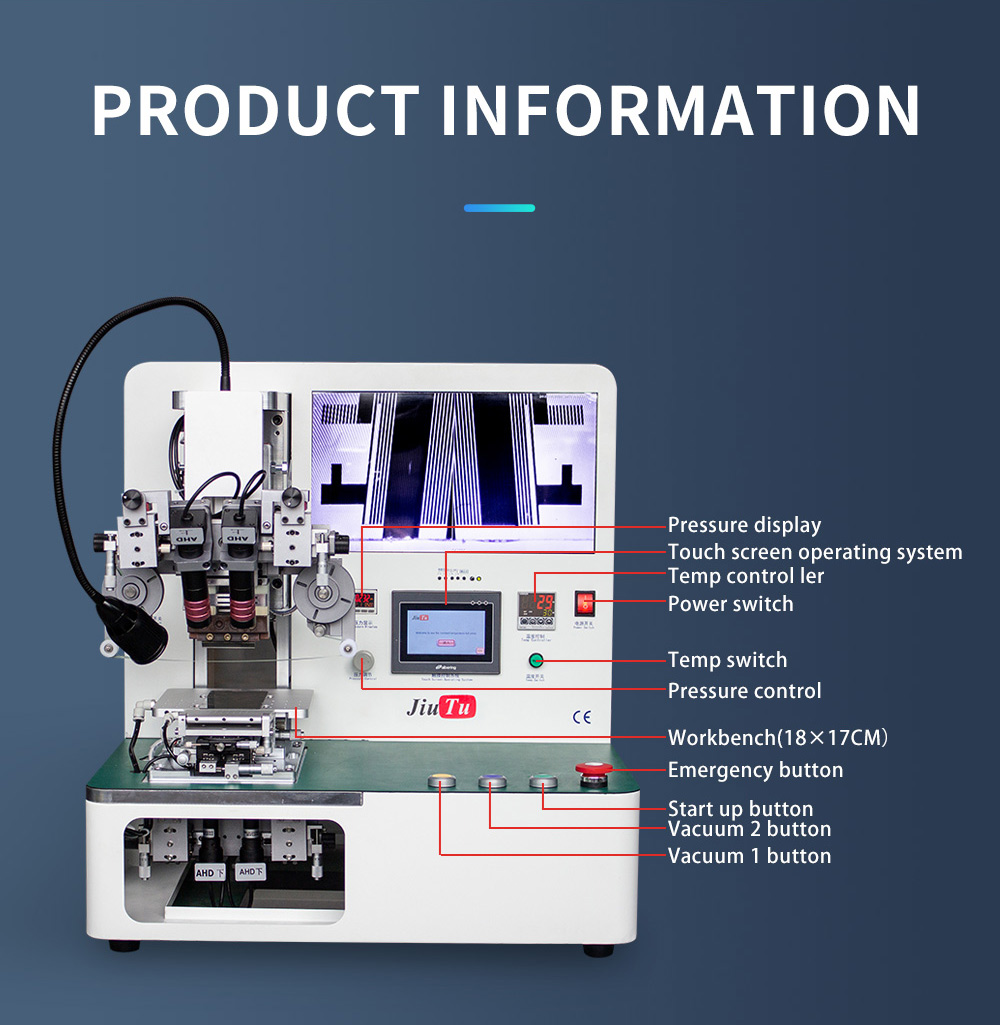

The length of the cutter head of the product can be customized within 90mm*width of 5mm; the temperature can be set at 0-450 degrees, and the pressure can be adjusted from 0-0.6mpa. The platform has a pre-heating function, and the camera can be positioned up or down according to the requirements, and the lens multiples can be configured according to the samples provided by the customer.

Main Features :

The constant temperature heating method is adopted, and the main structure is made of 45# steel with high precision and good stability. Using Japanese SMC cylinder + precision pressure regulating valve to precisely control the pressing force. Imported thermal insulation module and special tungsten steel cutter head are used for durability and high temperature accuracy. HD auxiliary alignment system.

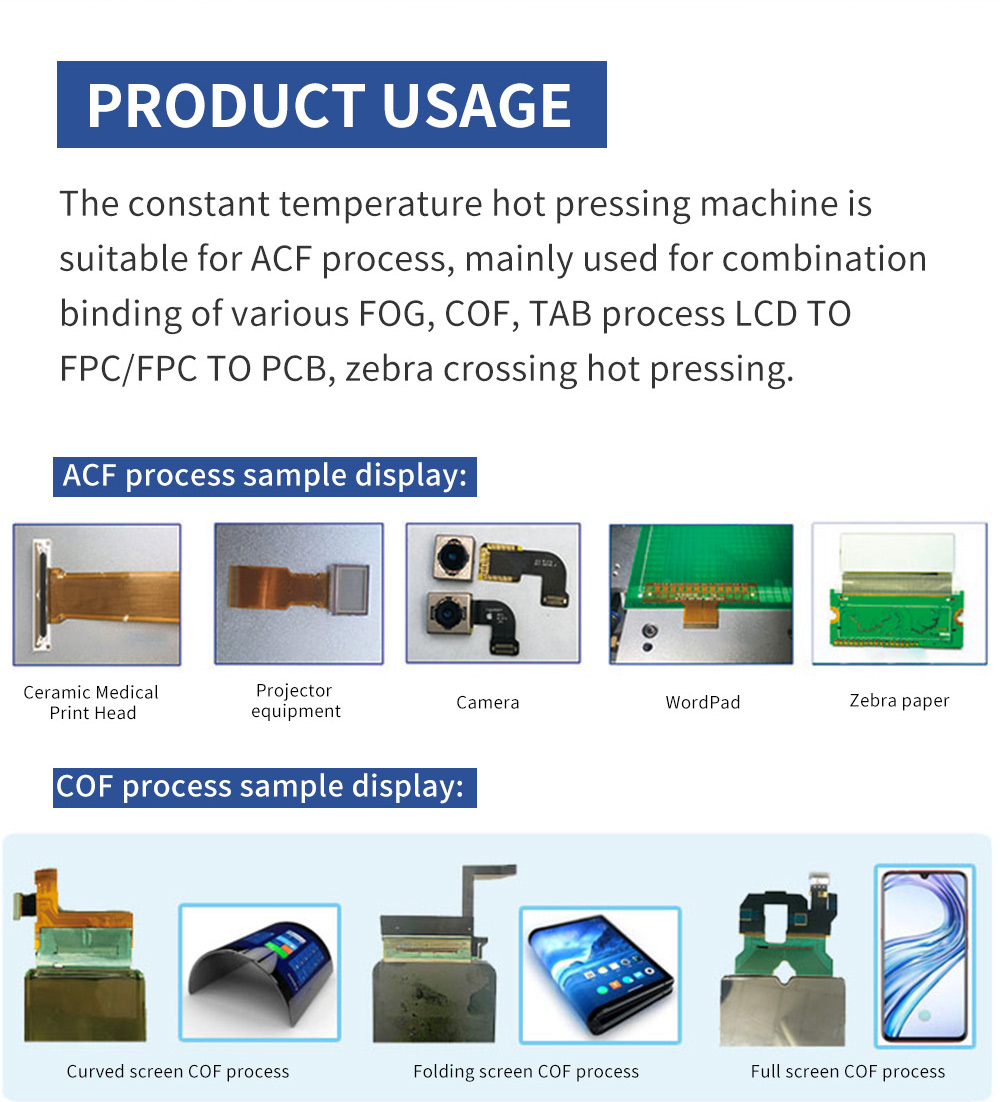

Working principle :The ACF glue process is mainly used to bind the chip, FPC or FFC cable together according to the pressure, temperature and time parameters of the ACF glue. According to the equivalent force and temperature output by the hot press, the ACF particles are hot-pressed and blasted at a certain time, so as to achieve the purpose of vertical conduction and horizontal non-conduction.

Working area :

1,Mobile phone cable binding field,

2,medical field,

3,laboratory research and development test

|

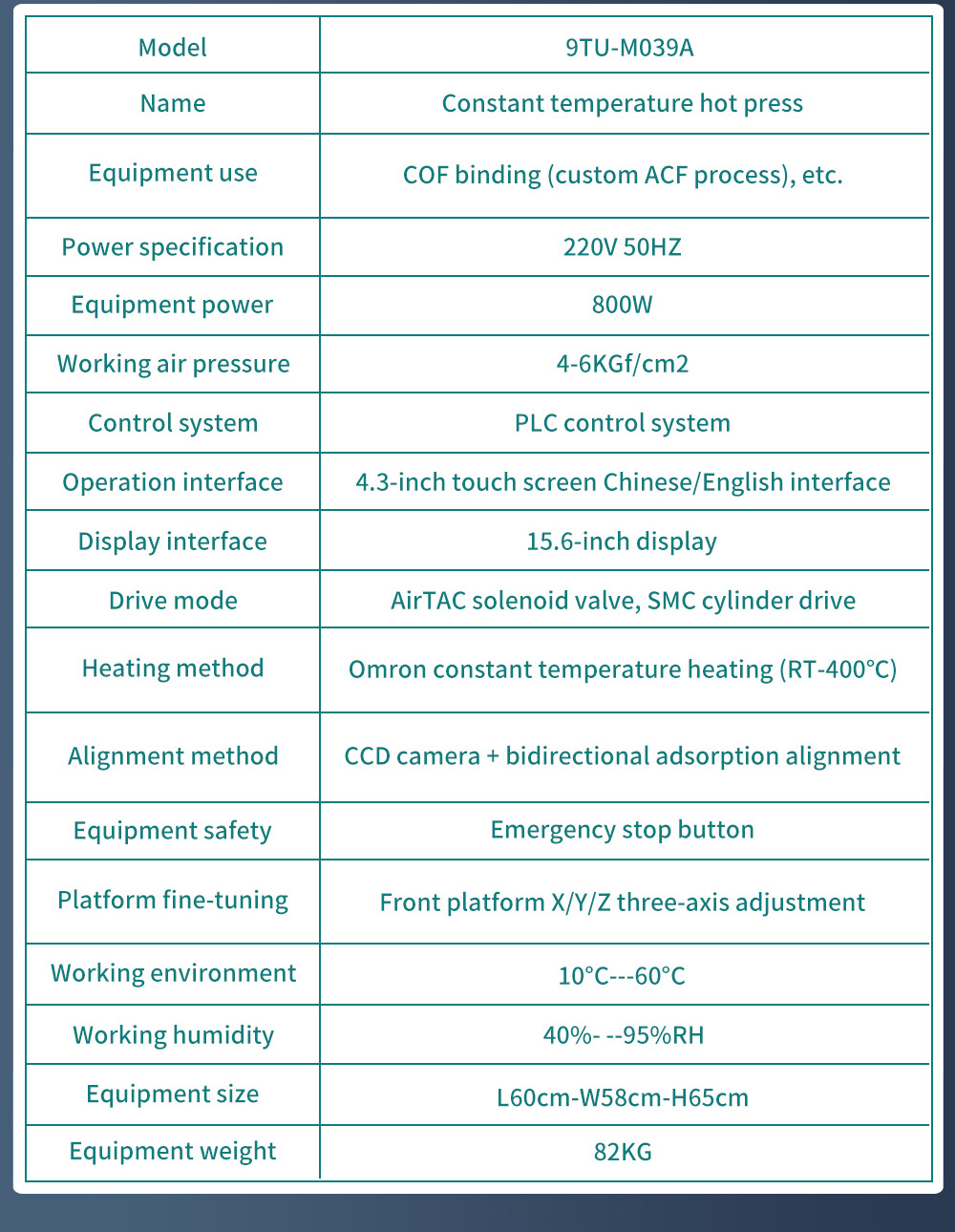

Model

|

FPC/FFC bonding machine

|

|

P/N

|

9TU-M039A

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 500℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|