New Delivery for Lcd Glass For Iphone Xr - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu

New Delivery for Lcd Glass For Iphone Xr - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu Detail:

Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

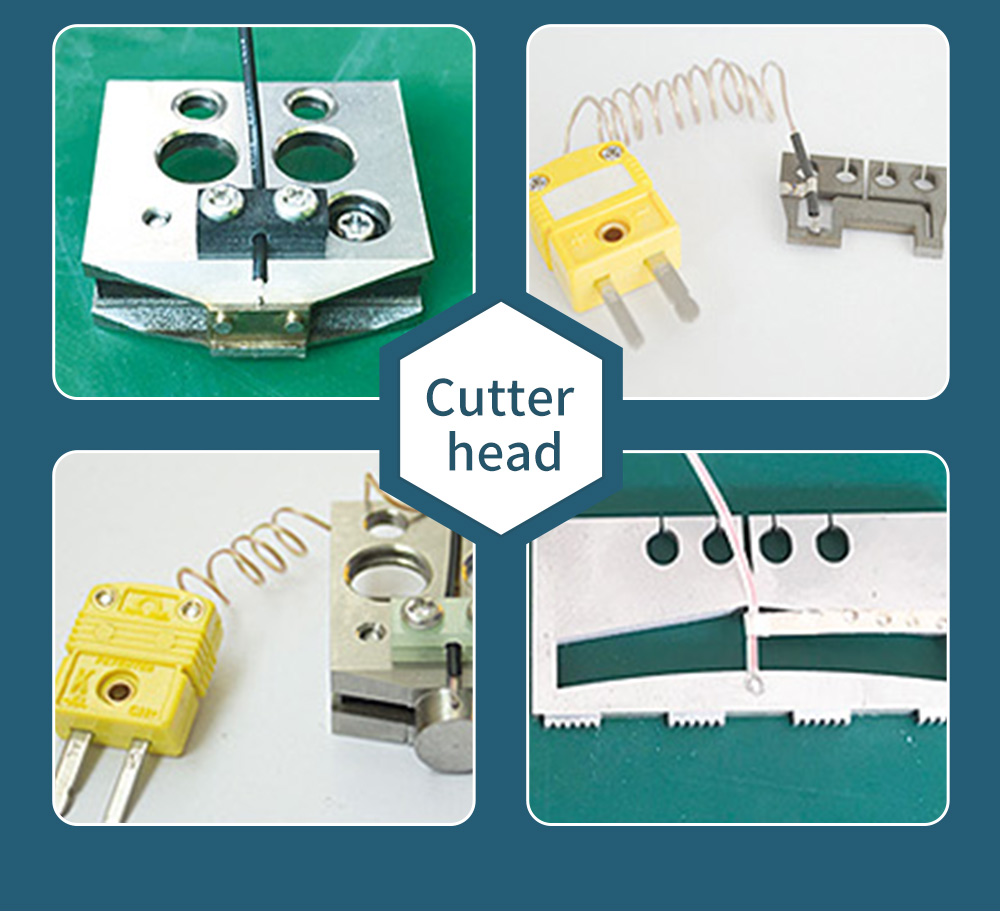

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Global Assembly Equipment Market Outlook 2019 – Kent Machine, Arnold Machine, Buckeye Machine, Sandvik Materials Technology | 2 In 1 Glass With Bezel Frame

Global Assembly Machine Market Insights Report 2019 – EMAG GmbH, Bystronic Glass | Air Bubble Removing Machine For Lcd Repair

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for New Delivery for Lcd Glass For Iphone Xr - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu, The product will supply to all over the world, such as: Guyana , El Salvador , Swiss , We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.