Hot New Products Glass Lens With Frame Cold Glue Press - Newest Customized Fixture Soldering Machine For Thermal Film Welding Jiutu – Jiutu

Hot New Products Glass Lens With Frame Cold Glue Press - Newest Customized Fixture Soldering Machine For Thermal Film Welding Jiutu – Jiutu Detail:

Newest Customized Fixture Soldering Machine For Thermal Film Welding Jiutu

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

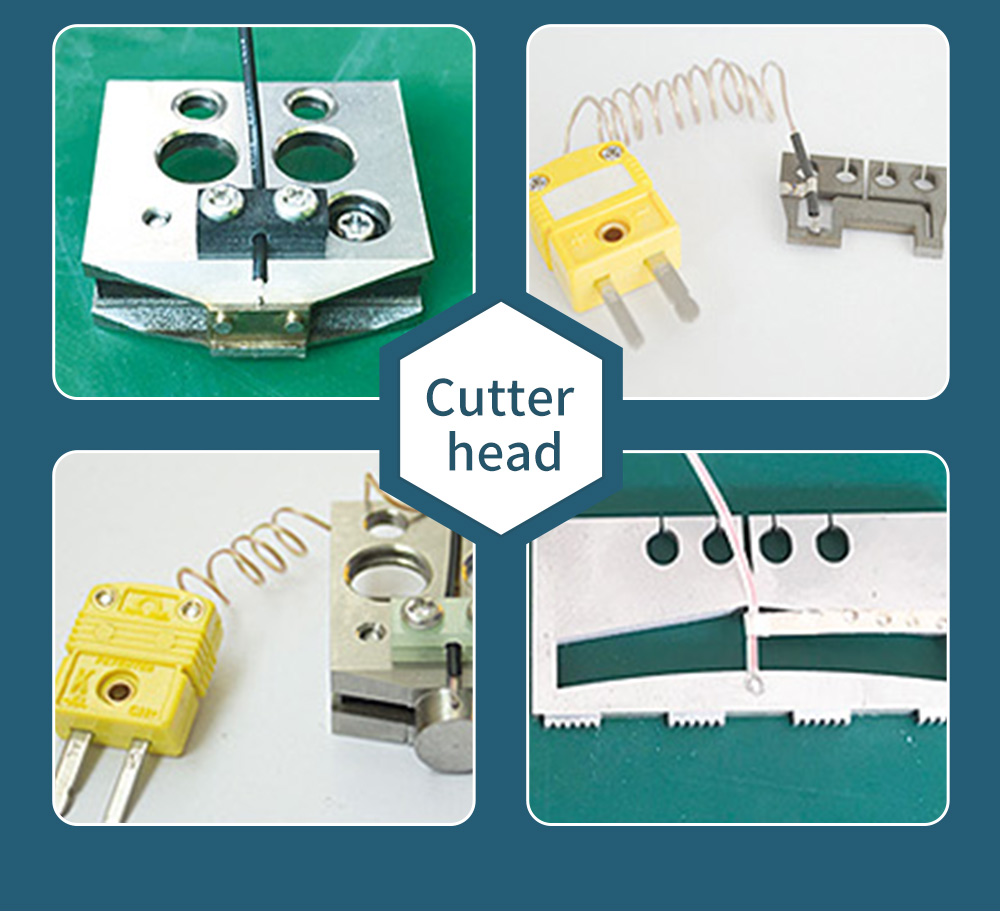

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Excellent growth of Motors and Actuators in Industrial Robots Market- Comprehensive study by key players: ABB, Applied Motion Products, FAULHABER, etc | Front Glass With Frame

Examine Source Code to Assembly Mapping with penguinTrace | Air Bubble Removing Machine For Lcd Repair

The corporate keeps towards the operation concept "scientific administration, superior quality and performance primacy, client supreme for Hot New Products Glass Lens With Frame Cold Glue Press - Newest Customized Fixture Soldering Machine For Thermal Film Welding Jiutu – Jiutu, The product will supply to all over the world, such as: Jordan , Suriname , El Salvador , We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!