Factory source Digitizer Flex Repair Machine - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu

Factory source Digitizer Flex Repair Machine - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu Detail:

Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

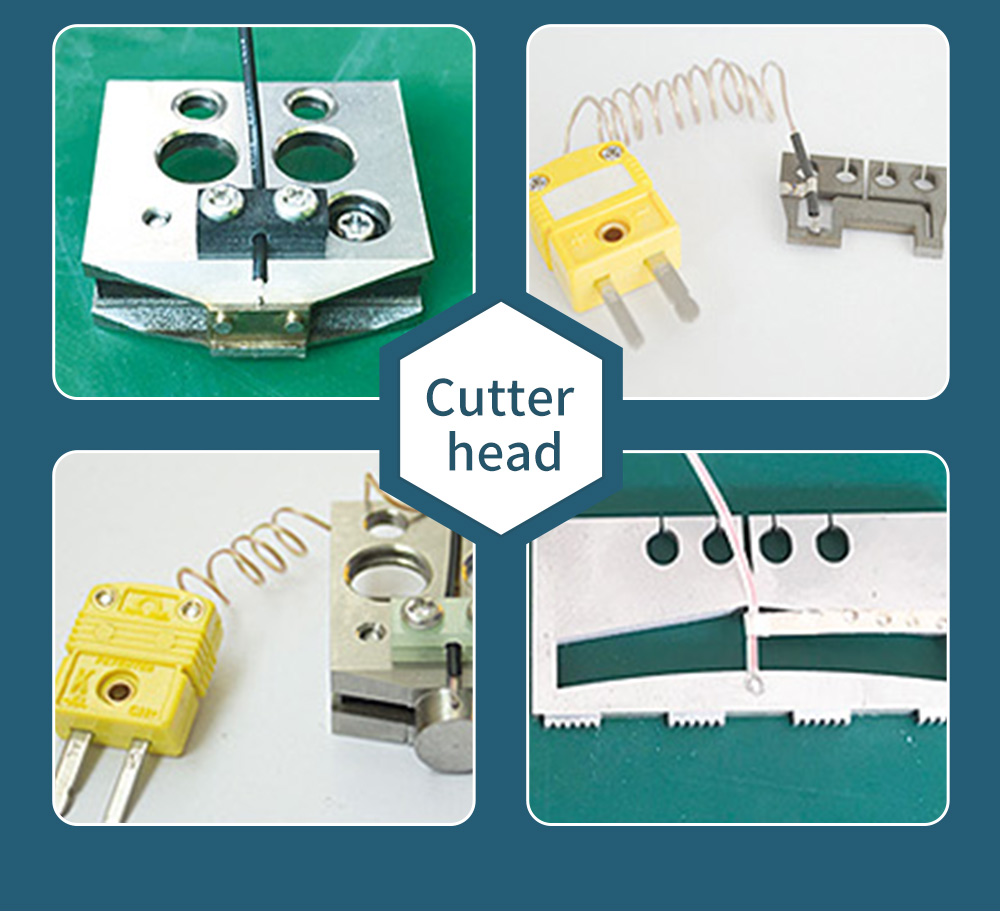

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Worldwide Industrial Robots Market in the Home Appliances Industry Market 2022: Industry Analysis (Vendors, Regions, Growth Rate) | Assembly Machine

Giving robots a better feel for object manipulation | Air Bubble Removing Machine For Lcd Repair

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Factory source Digitizer Flex Repair Machine - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu, The product will supply to all over the world, such as: Paraguay , Jersey , Bolivia , We welcome customers from all over the world come to discuss business. We supply high quality products, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.