Factory Price For For 7 Plus Cracked Lcd Refurbish - 150 Degree Vacuum Hot Press Laminating Machine Gaskets on Membrane For PEM Fuel Cell Lamination – Jiutu

Factory Price For For 7 Plus Cracked Lcd Refurbish - 150 Degree Vacuum Hot Press Laminating Machine Gaskets on Membrane For PEM Fuel Cell Lamination – Jiutu Detail:

150 Degree Vacuum Hot Press Laminating Machine Gaskets on Membrane For PEM Fuel Cell Lamination

Product Introduction :

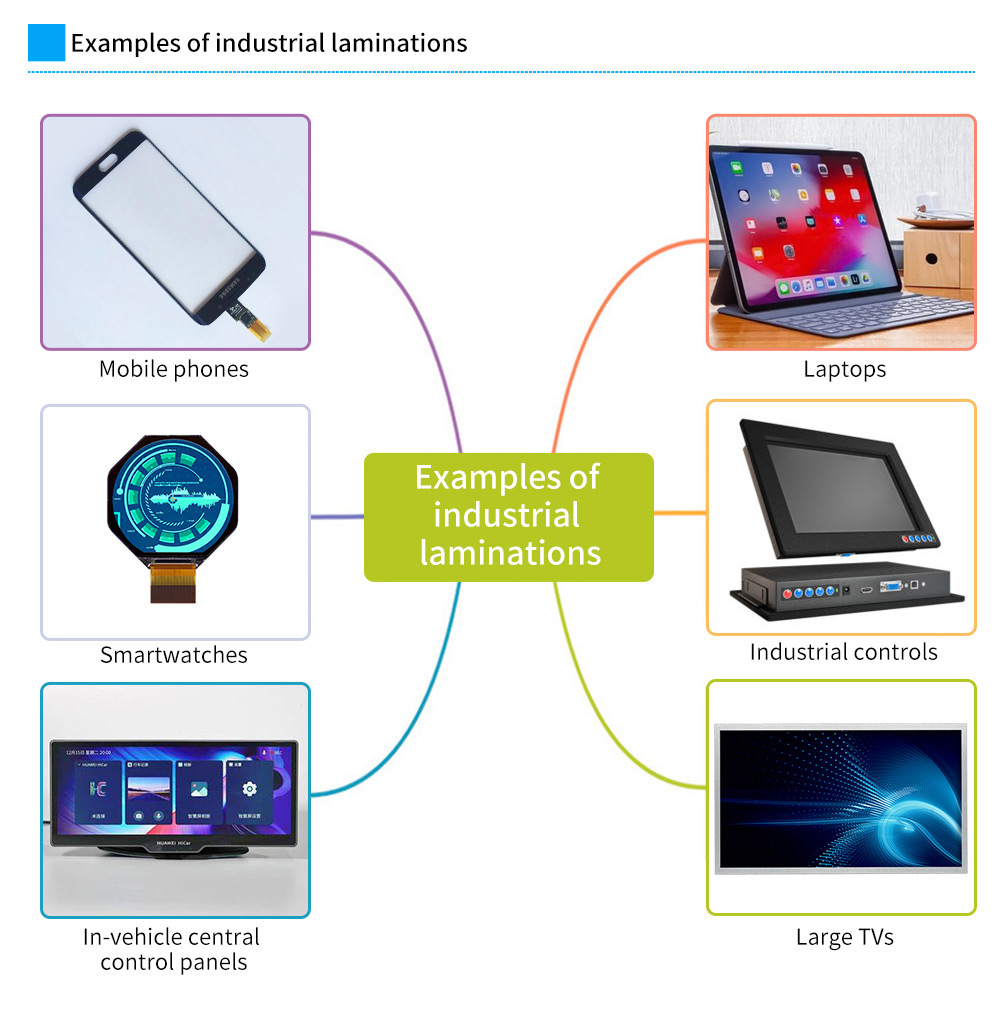

SCA, COF, and other hot-melt adhesive vacuum lamination and hot-press lamination, SCA/OCF and other hot-melt adhesive processes for medium and large size G+G and full lamination;

Large-size vacuum laminating machine is specially used for laminating large-size hard-to-hard (G+G) hot-melt adhesives. This machine has the function of pressurizing and heating in a vacuum state, and is suitable for OCA.OCF.TPF and large.COF .Medium and large size G+G full lamination in SCA and other hot melt adhesive processes, OCA process G+G lamination, suitable for naked eye 3D and TP/LCM full lamination of various sizes

SCA, COF, and other hot-melt adhesive vacuum lamination and hot-press lamination, SCA/OCF and other hot-melt adhesive processes for medium and large size G+G and full lamination;

Large-size vacuum laminating machine is specially used for laminating large-size hard-to-hard (G+G) hot-melt adhesives. This machine has the function of pressurizing and heating in a vacuum state, and is suitable for OCA.OCF.TPF and large.COF .Medium and large size G+G full lamination in SCA and other hot melt adhesive processes, OCA process G+G lamination, suitable for naked eye 3D and TP/LCM full lamination of various sizes

Main Features :

1. High Temperature vacuum laminator fit for LCD Screen up to 32 inches , lamination area size 510*710mm

2. Customized mold will be necessary based on the actual product

3. Work fast needs 25-40 seconds for each time. depend on the product

4. Fully automatic , easy operation

5. It is mainly suitable for the bonding of hard plastic chips such as PMMA, PC, PP, COP, COC, BOPET, CBC, resin (part), polyethylene (part), etc.) The maximum temperature is 150 degrees; the maximum pressure is 10KN.

Specification :

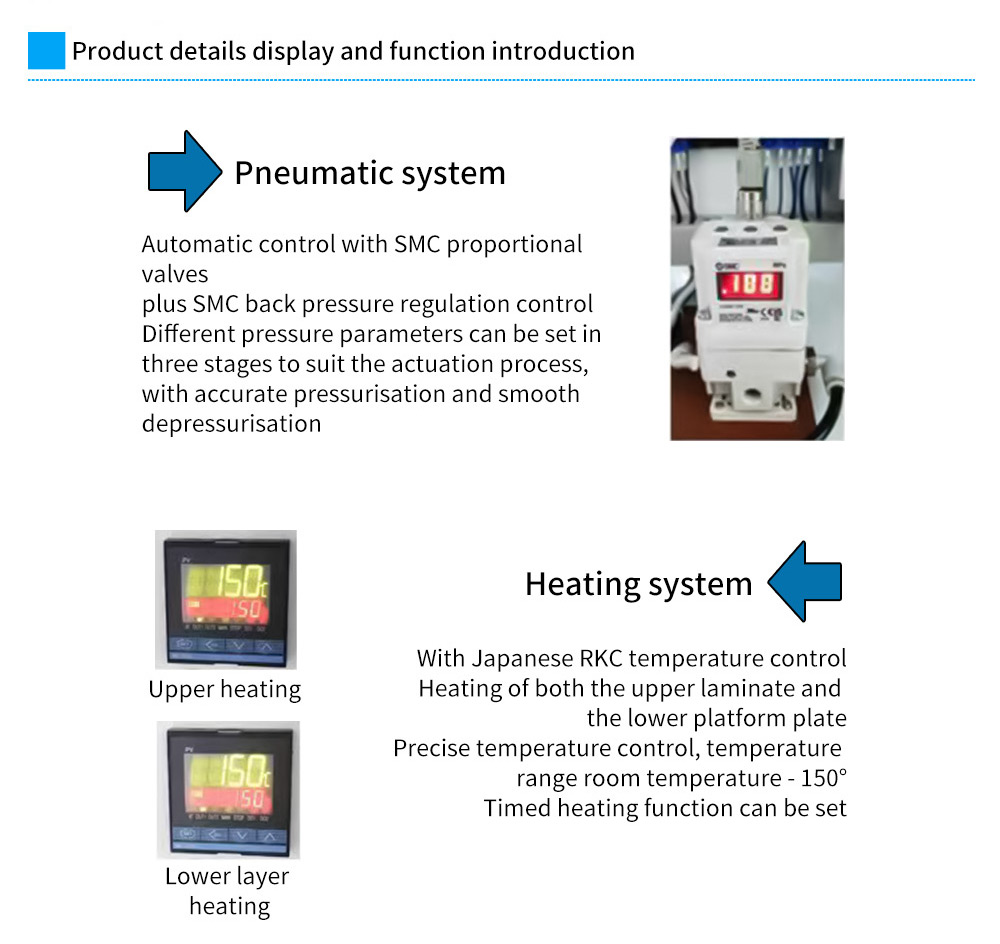

1. Using up and down heating, the temperature can be set up to 150 degrees.

2. The working platform can adjust the balance function.

3. The maximum pressure can reach 1.2 tons.

4. The action of the equipment is driven by a cylinder

Working principle :

Vacuum hot press is a complete set of equipment for hot-pressing materials under vacuum conditions; it mainly uses resistance heating, pressurized by the pressure head of the cylinder, and hot-melts the hot-melt adhesive under high-temperature and vacuum conditions to bond two objects Together, hardness and other mechatronic thermal properties.

Working area :

1,University laboratory test, company laboratory test, medical field,

2, Laboratory research and development equipment

|

P/N

|

9TU-M040D

|

|||

|

Model

|

150 Degree Vacuum Laminator Hot Press Machine

|

|||

|

Brand

|

Jiutu

|

|||

|

Lamination Size

|

Under 32 inches

|

|||

|

Tempature Range

|

up to 150℃

|

|||

|

Success Rate

|

99%

|

|||

|

Working Rated Power

|

7KW

|

|||

|

Net Weight

|

600kg

|

|||

|

Warrantty

|

2 Years

|

|||

|

Working Temperature

|

Normal temp till -150 ℃ all works

|

|||

|

Working Pressure

|

0.4-0.8Mpa can be adjusted

|

|||

|

Volatge,Power Supply

|

380V 50Hz

|

|||

Product detail pictures:

Related Product Guide:

Hewlett Packard Enterprise BrandVoice: Watchful Intelligence | Front Glass With Frame

Razer Phone 2 vs. Black Shark 2: Gaming flagships face off | Assembly Machine

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Factory Price For For 7 Plus Cracked Lcd Refurbish - 150 Degree Vacuum Hot Press Laminating Machine Gaskets on Membrane For PEM Fuel Cell Lamination – Jiutu, The product will supply to all over the world, such as: Iran , Florida , Puerto Rico , We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.