Factory made hot-sale Lcd Touch Screen Separator Machine - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu

Factory made hot-sale Lcd Touch Screen Separator Machine - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu Detail:

Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

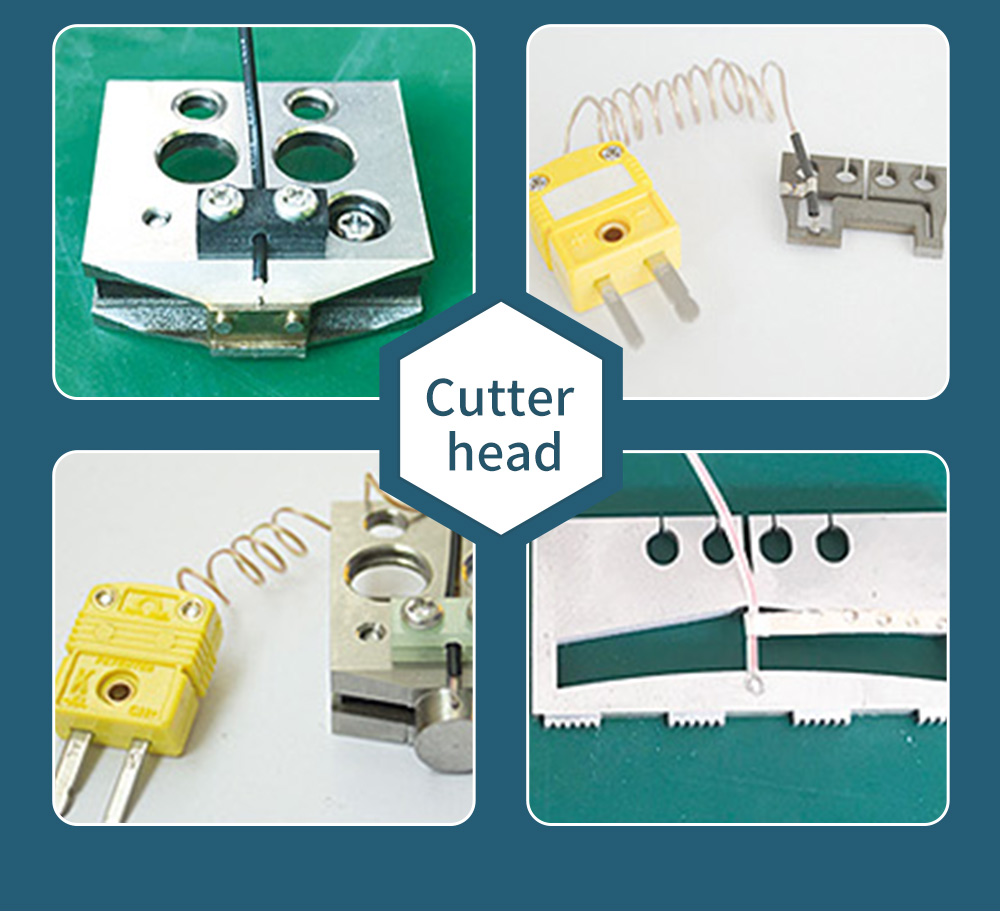

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Assembly Machine Market Disclosing Latest Trends and Advancement 2019 to 2025 | Air Bubble Removing Machine For Lcd Repair

Mitsubishi Electric invests in Realtime Robotics’ motion-planning technology | Assembly Machine

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Factory made hot-sale Lcd Touch Screen Separator Machine - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu, The product will supply to all over the world, such as: Portland , Liberia , United Arab Emirates , With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!