China OEM Glass Separator Machine To Repair - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu

China OEM Glass Separator Machine To Repair - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu Detail:

Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

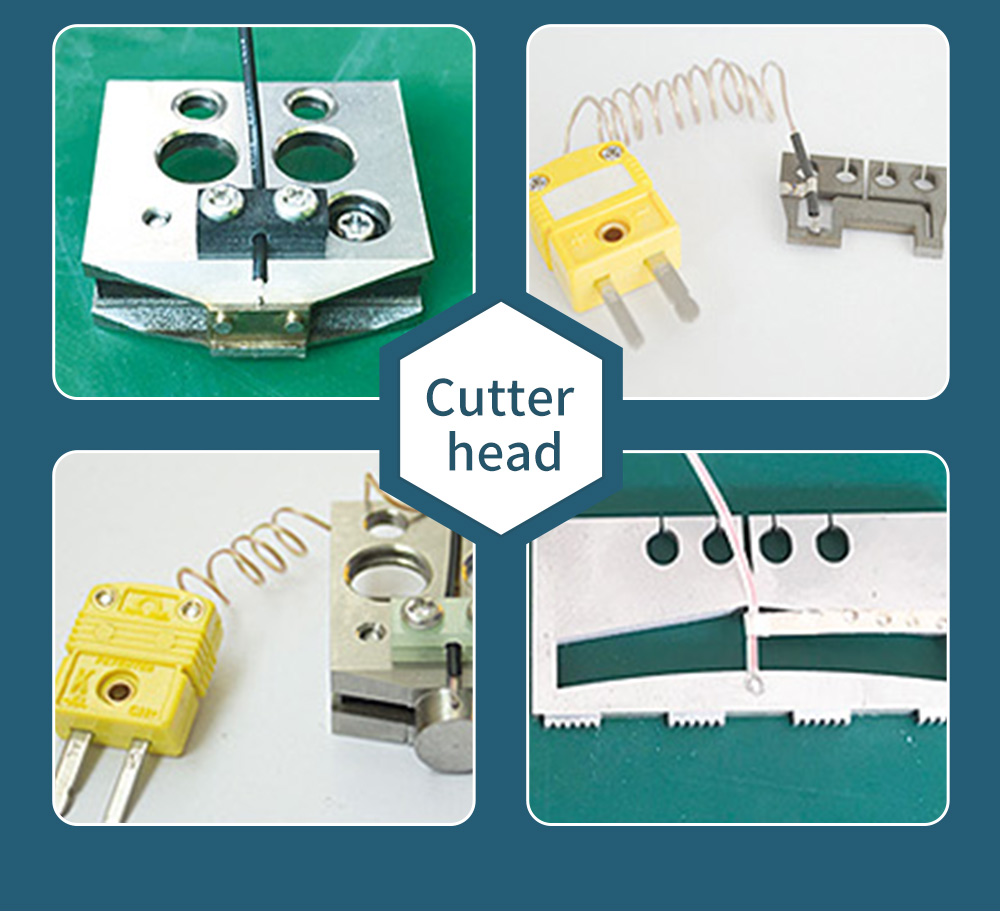

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

GLOBAL ROBOTIC CUTTING, DEBURRING, AND FINISHING MARKET RESEARCH REPORT, MARKET SIZE, STATUS, REVENUE, CONSUMPTION, IMPORT AND FUTURE FORECAST TO 2019-2024 | Assembly Machine

iPhone XS drop test: This phone would not crack | 2 In 1 Glass With Bezel Frame

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for China OEM Glass Separator Machine To Repair - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu, The product will supply to all over the world, such as: Seattle , Greenland , Maldives , We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.