2017 High quality Phone Spare Parts - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu

2017 High quality Phone Spare Parts - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu Detail:

Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

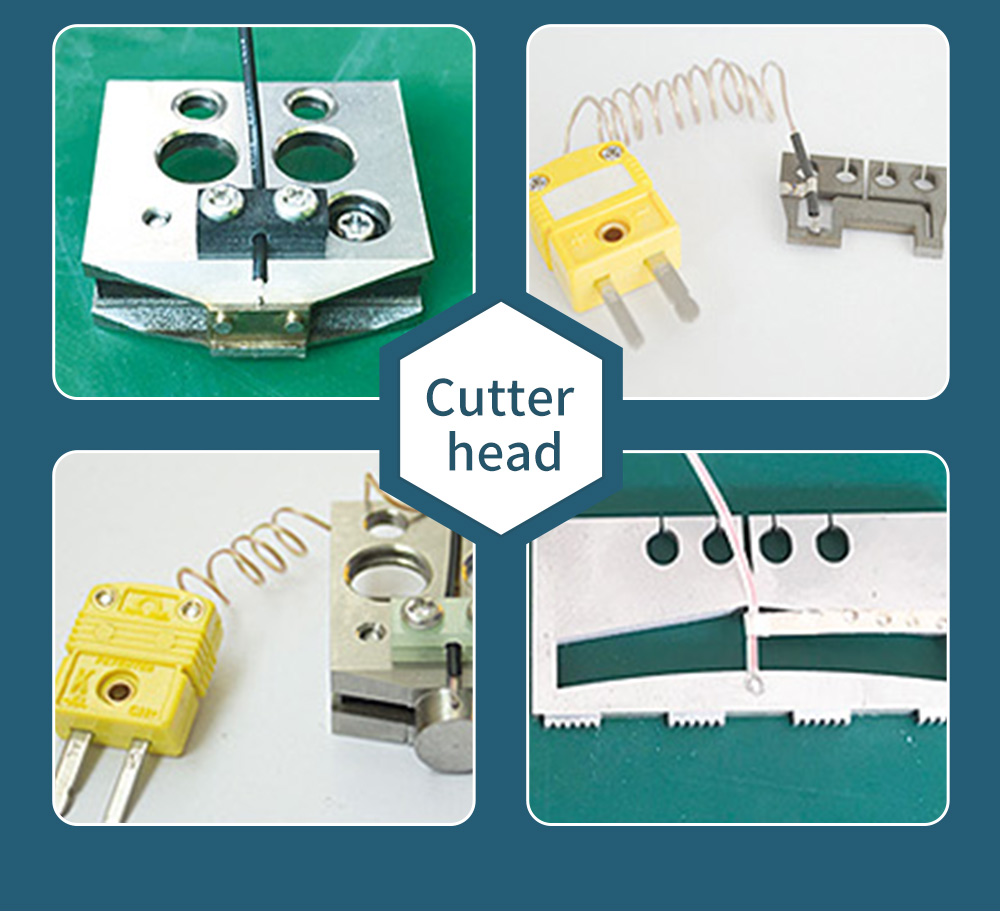

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Cable Assembly Market 2019-2025 – Global Trends, Statistics, Size, Share, Regional Analysis by Key Players, Application & Products. | Industrial Robots

Twelve South Launches ‘PowerPic’ Wooden Picture Frame With 10W Qi Charger for $80 | Air Bubble Removing Machine For Lcd Repair

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for 2017 High quality Phone Spare Parts - Max 600 Degree FFC FBA Hot Pressing Machine For Chip Soldering – Jiutu, The product will supply to all over the world, such as: Bulgaria , Iceland , Algeria , When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!