18 Years Factory Front Glass For Iphone - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu

18 Years Factory Front Glass For Iphone - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu Detail:

Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

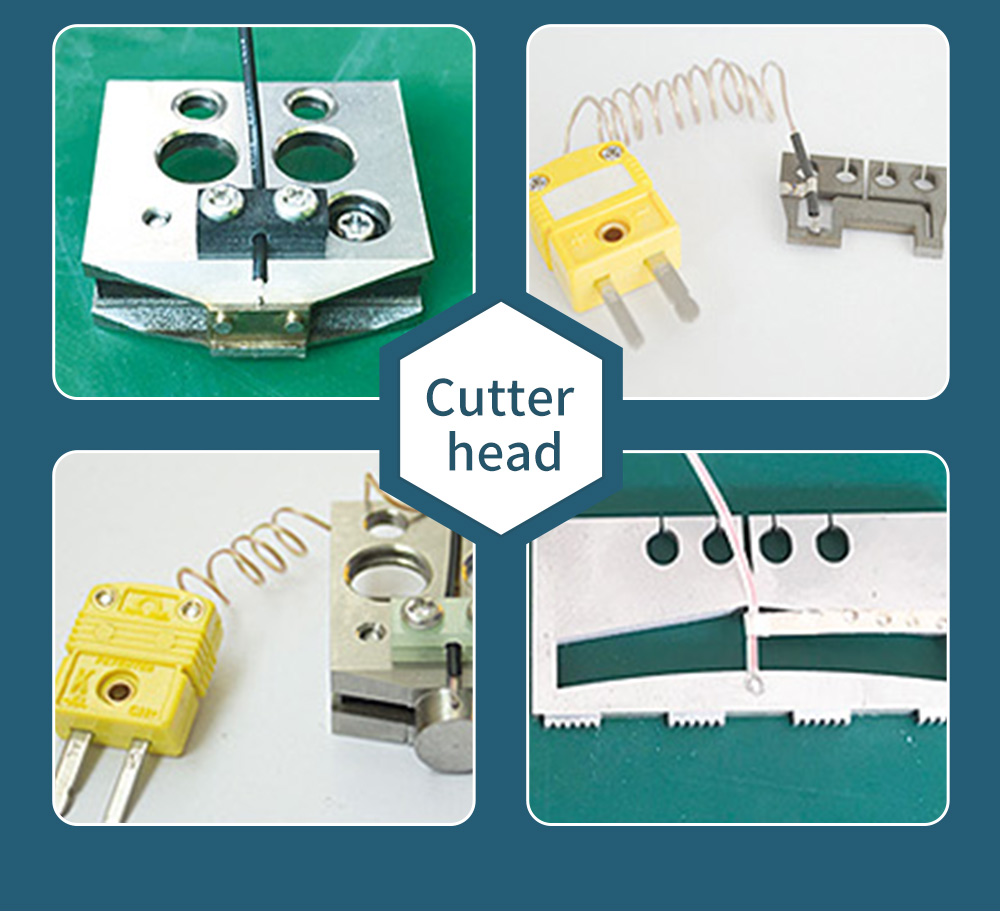

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Scratches are a huge problem for iPhone XR and XS screens, so get these $4 screen protectors | Industrial Robots

Video shows L.A. Deputy Caren Carl Mandoyan trying to break into woman’s home, leading to his firing | Assembly Machine

We have our own product sales staff, style crew, technical group, QC staff and package staff. We now have strict high quality management procedures for each approach. Also, all of our workers are experienced in printing subject for 18 Years Factory Front Glass For Iphone - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu, The product will supply to all over the world, such as: Romania , British , Sao Paulo , Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.